24 Hr Emergency Response

800-377-3648

10,000 Environmental Remediations Since 1975

Remtech © 2024

| CAREERS |

| Contact Us

Location: Central Georgia

Client: Major Railroad

Contract Amount: $36,500

PROBLEM

An at-grade collision between a train and low-boy

truck ruptured the lead locomotive’s fuel tank on a

mainline track running next to a drainage ditch. The

train traveled 1,787 ft prior to stopping releasing an

estimated 1,000 gallons of diesel fuel.

SOLUTION

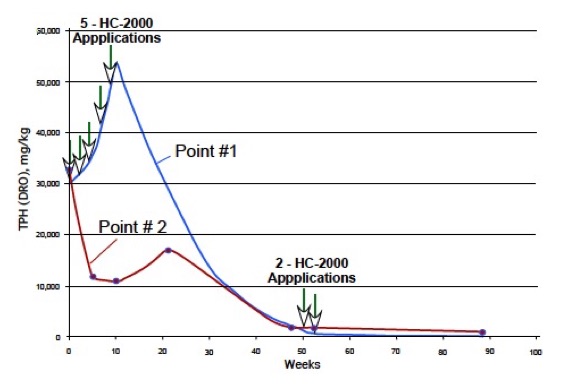

Five (5) HC-2000 applications were made to the

tracks and ballast during the first three months from

an access road parallel to the tracks. Two (2)

additional applications were made six (6) months later

followed by six (6) month degradation period.

Total petroleum hydrocarbon (TPH) concentrations

were reduced 97% at Impact Point 1 and a 99%

reduction was achieved at Rest Point 2. A no further

action letter was obtained from the State Department

of Natural Resources.

COST/BENEFITS

Treatment of track bed ballast with HC-2000 was

several orders of magnitude less expensive than

excavation and replacement considering track service

interruption time.

HC2000 sprayed over 1,787 ft of Track Diesel Fuel Spill

HC-2000 applied to Track Cross Sections with Fire Nozzle

from Access Road

Diesel Spill Ballast Bioremediation at Rail Crossing at-grade Collision Site with HC-2000 | Warner Robbins, GA

Diesel Fuel Degradation Fuel in Track Ballast