What’s New?

Remtech Engineers is one of the largest OSRO inland rapid water response firms in the SE... Adding two Guzzler Vacuum Trucks with Hi-rail; invented VacuJet TM (combined jetting & vacuum) heavy solids sewer/pipeline cleaning system capable of cleaning 300 ft sections; constructed pollution prevention facilities for a major railroad in six states; remediated a major speciality chemical fire; investigated, located, and remediated a leaking fuel line under a large intermodal railyard; completed a large diesel fuel groundwater remediation at a major bus terminal with integrated HC-2000 injection and total fluids extraction; and stockpiling 2,000 gallons of Remtech’s proprietary HC2000 capable of treating impacted shorelines and soils for 4,000,000 million gallons of petroleum hydrocarbon releases.

Major Fast River Mineral Oil Response at Power Plant - $100,000

Remtech responded to a power plant transformer explosion and fire that released mineral oil into the Chattahoochee River with a velocity exceeding 2 ft/sec. Remtech coordinated the fast water recovery with 3 other contractors, installing a 300 ft river bank diversion boom, 3 bank containment and river recovery booms, oil skimmers, recovery pumps and vacuum trucks, frac tanks, and tankers for treatment of recovered oil and contact water.

Remtech FRACAIR Magnetic Aeration System Deployed in Temporary Wastewater Treatment Plant - $430,000

Remtech constructed an 60,000 gpd emergency frac tank wastewater pre-treatment plant for a major food manufacturing facility while a new plant was being constructed. This avoided the manufacturing being shutdown. Remtech's patent pending FRACAIR system was installed in 3 - 21,000 gallon rented frac tanks that created an equalization system. FRACAIR is designed to fit through a 20" manhole in less than 1 hour and is powered by a 5 Hp rotary lobe blower. A serpentine alum and sodium hydroxide floculation/neutralization system was fabricated and a new micro-bubble pump was installed to renovate an existing dissolved air floatation system. The temporary treatment system operated for a period of 10 months while a permanent plant was being constructed.

Remtech Mercury Decontamination at Hydroelectric Facility - $450,000

Remtech Engineers was engaged by one of the largest hydroelectric turbine manufactures to investigate, provide emergency PPE and decontaminate and remediate a production facility mercury release. Mercury was found on concrete and metal surfaces. The source of mercury was due to failure of a bearing in the hydraulic reactor loop and test lab. Remedial measures included draining and cleaning the reactor and reservoir, cleaning floors under the test loop, elemental mercury recovery from tanks, test loop, and production equipment components.

PFAS Mobile Treatment Design of AFFF Fire Runoff Water at Manufacturing Plant

Remtech designed a PFAS treatment system to treat 500,000 gallons of AFFF fire runoff water containing PFAS concentrations ranging from 253,649 ppt to 13,185,500 ppt. The treatment system consisted of screening, equalization,

sedimentation, non-harvesting aeration/foam fractionation, sand filtration, and three-stage Granular Activated Carbon Filtration (GAC). PFAS concentrations were reduced below 200 ppt for treatment at an existing WWTP. Remtech also developed a rapid 30 second field COD correlation test to predict final laboratory PFAS concentrations.

HC-2000 Integrated Total Fluids Extraction Diesel Groundwater Cleanup

- $850,000

Remtech remediated a diesel fuel release from a ten-thousand gallon underground storage tank and secured reimbursement from a State’s Leaking Underground Trust Fund. Remtech’s two-phase vacuum extraction system consisted of a rotary claw blower, dissolved air floatation (DAF), oil/water separator, multimedia and activated carbon filters, and injections of Remtech’s proprietary HC-2000 biostimulation bioremediation accelerator. Seventeen (17) recovery wells were drilled in tight clay soils (conductivity of 6.3 x10-6cm/sec) and groundwater that contained elevated concentrations of iron bacteria floc. Calcium chloride was added to the DAF system to facilitate fuel separation from floc.

For every gallon of fuel recovered, one-gallon of biosolids had to be removed. 2,000 gallons of fuel were recovered over a four-year period. Seven injections of Remtech’s proprietary HC-2000 biostimulation accelerator completed the project and received a No Further Action Letter from the State.

Pollution Prevention Structures Installed at Six Railyards - $1,500,000+

Remtech was authorized to construct pollution prevention and control systems at railyards in six states.

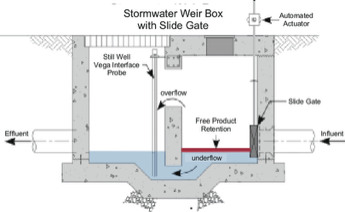

Stormwater diversion and containment facilities consisted of: earth/rock & concrete containment dikes; clean water diversion swales; new stormwater

manholes and connecting piping; Remtech 50,000 lb precast in ground stormwater underflow weirs with automated sluice gates and hydrocarbon detectors; secondary containment piping; automated fuel control valves with leak detection installed on fuel storage ASTs; and footings and column supports for overhead fuel pipe bridges.

VacuJetTM (Combined Jetting and Vacuum) Cleaning of Long Pipe Sections

- $50,000

Remtech was engaged to clean heavy oily sand deposits from an engine terminal’s 24-inch, 1,000 ft long DIP wastewater sewer that could not be cleaned by conventional jetting techniques. Two additional manholes were installed to reduce cleaning distances to 300 ft. Remtech’s proprietary VacuJetTM is a combination jetter/cutter head attached to a 4-inch vacuum line. A high-tension synthetic rope glide system advances the cleaning head and vacuum line through 90 degree angles and 300 ft pipe sections. 11,750 gallons of heavy sludge were removed.

Chemical Plant Fire Restoration - $350,000

Remtech responded to a chemical plant fire containing aromatic chlorinated solvents and propellants. Remtech’s fire restoration activities included: cleaning bulk storage tanks, totes, drums, secondary containment structures, overhead pipe racks, processing equipment, pollution control systems, buildings. Hazardous products were transferred to frac tanks and tankers for disposal. A carbon filtration system installed in a detention basin overflow structure removed soluble organics from several million gallons of stormwater runoff.

Pipeline Fuel Leak Remediation at Intermodal Yard - $350,000

Remtech determined the leak location, contained, recovered, and supported leak repair operations for a 3,500 foot underground fuel line. A total of four 20 ft deep test pits were excavated to uncover the pipe. The leaking pipe segment was located by installing valves in two test pits and pressure testing each section. 350 ft of new pipe was replaced, welded, x-rayed, and pressure tested.

One million gallons of stormwater and petroleum contact water were pumped from test pits and disposed of at the railyard’s onsite treatment plant and an offsite pretreatment facility. Two-phase vacuum extraction operations removed mobile free product.

Thank you . . .

. . . to all our friends and clients for extending the opportunity to allow us to earn the right to become your preferred environmental services provider!

REMTECH NEWS FLASH AND ASSISTANCE REQUEST

For Immediate Release - Remtech April, 1, 2024 News Flash

Rapid Deployment Spill Response Trailers

(2300 ft boom, boats, skimmers, and spill recovery.

(Elastic Drum Skimmer Recovers 97% Fuel)

Integrated Total Fluids Extraction & HC2000 Injection System Remediation at UST Diesel Release Site

Remtech 50,000 lb Precast Stormwater Pollution Prevention Weir Box with Automated Sluice Gate and Hydrocarbon Sensor Prevents Fuel Releases

Chemical Plant Fire Response & Restoration

Investigation & Remediation of Major Pipeline Leak at Intermodal Yard un 22 sets of tracks

Since our founding in 1988, we have completed over 10,000 environmental remediation projects. Thanks to our many customers, Remtech’s facilities and sales have increased! New capabilities include: combustible dust cleaning, development of magnetic aeration systems installed in Frac Tanks for temporary wastewater treatment, mercury remediation at major hydroelectric plant, underwater drone inspections of highrise detention basins, and mobile PFAS wastewater treatment and rapid PFAS testing.

Please fill out the form below and indicate if you would like to be added to our mailing list to receive our news letters or need assistance on a specific project. We will get back to you quickly.

Mark Ryckman, P.E. BCEE

CEO & Founder

Emergency Fast River Response to Power Plant Electrical Fire Mineral Oil Release

Major Mercury Cleanup at Hydroelectric Plant Turbine Manufacturing

FRACAIR Frac Tank Magnetic Aeration System for

Wastewater Treatment